WTG Blog

Designing My First Product

October 11, 2017 - by Matty D

In my last post I was singing the praises of drafting and computer aided design (CAD). I was particularly excited about a product called Sketchup. I was saying that anybody who builds things would be better off they were able to draw them out before the actual work begins. And it just so happened that I had a project in mind, So I followed my own advice and drew it up.

I am working on the rear axle of my 1993 Toyota 4-wheel drive pickup truck. It needs new brake backing plates. The existing backing plates are badly corroded from road salt. The backing plate is part of an assembly that consists of the axle, the wheel bearing, the backing plate and a retaining collar. The assembly is pressed together and secured with a snap ring. In order to separate the backing plate from the rest of the parts it has to be pressed apart.

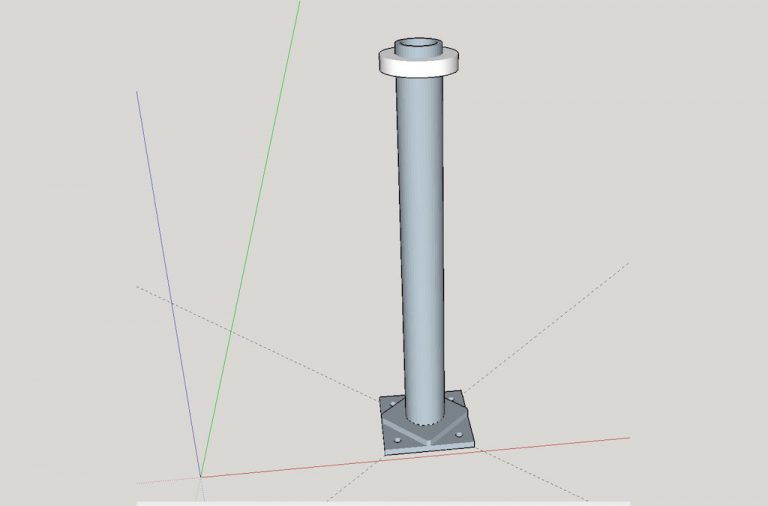

I already had a little 12-ton hydraulic press, but I didn’t have the tool. I anticipate doing more than one or two of these jobs so I decided I needed to have the tool. The first one I saw was offered on Amazon.com. A dissatisfied buyer posted pictures of the tool with a bent bottom plate. That didn’t stop me from trying to cobble together a replica of that tool from 1-1/2″ schedule 40 pipe and some quarter inch steel flat stock that I had lying around. That was a dismal failure. The quarter-inch stock was no match for the 12 ton press and neither were my welds. This got me thinking that I ought to do the job right and so I sat down at the computer and fired up the free 3-D modeling software, Sketchup.

Once I was satisfied with my drawing, I produced a materials list. The bottom was going to be made of two pieces of 3/8″ flat stock, the tube that makes up the main body would be 2 1/4 inch OD with quarter inch walls. The collar on the top that the tool would hang from in the press was made out of a slice of 3-3/4″ OD steel tube with three-quarter inch walls. I sourced the steel from speedy metals in new Berlin Wisconsin. They have an excellent Internet store for Ordering metal which you can then have shipped. They also have local pick up. I didn’t have time to drive the 80 mile round trip, so I ordered the metal to be shipped. The total bill for the steel was around $32, plus $10 for shipping

Recent Comments